They excel in producing small, complex elements with limited tolerances, as being the proximity in the headstock to the workpiece enhances accuracy and decreases deflection in the course of machining.

By incorporating drilling and dull tools, the headstock empowers the CNC lathe machine to make exact holes, threads, and bores while in the workpiece. This ability facilitates the production of intricate models, the assembly of factors, and the incorporation of fasteners.

INDEX & TRAUB turn-mill centers established the standard for economic, high-precision solutions customized to The shopper's wants. Specifications ranging from the traditional production turning machine to tailor-created machining cells equipped with managing units.

It’s essential to Notice that within Each individual sort, there can be versions and customizations to accommodate precise machining needs. CNC lathe producers may well give distinctive designs and configurations of headstocks to meet the diverse needs of their buyers.

A notable characteristic in modern CNC lathes is Reside tooling. This allows tools to maneuver and function when the workpiece is stationary, enabling drilling, milling, and tapping functions without eradicating the workpiece from your lathe.

Selecting the right CNC lathe for your preferences can be a recreation-changer. get more info Here i will discuss The crucial element things to contemplate:

Instance: A lathe with a turret that holds 12 tools allows for complex machining without frequent tool adjustments.

Our instruct lathes are designed with robust, stable, and wider bed way for max vibration absorption. The entire mattress features outstanding structural rigidity. Dovetailed carriage and cross slide are hardened, high precision floor, coated with Turcite-B and scrape finished to make sure uniform surfaces.

Repeatability is about regularity. Can your machine strike that same spot time and again once more? With top rated-notch CNC lathes, we’re talking about a repeatability of 0.002mm. It’s like hitting a bullseye consistently in darts, but at a microscopic degree.

The headstock in machining centers is created for versatility, providing specific Command around both of those the spindle as well as the workpiece positioning.

The headstock’s flexibility extends to tapping functions, enabling the generation of threaded holes within the workpiece. By using correct tooling, the headstock allows create threads of various measurements and pitches, maximizing the performance and versatility from the manufactured parts.

This enables organizations to supply a versatile response to shopper requirements and infrequently earn back again work from overseas producers.

CNC sliding headstock lathes from TRAUB are created for correct and successful producing of long and slender parts with a most diameter of 32 mm.

Usually quite a few clampings would be necessary to complete the parts, or occasionally extremely distinct transfer machines is also used, nevertheless the financial investment could be Considerably higher. To permit this indexation and...

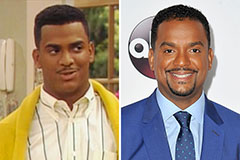

Alfonso Ribeiro Then & Now!

Alfonso Ribeiro Then & Now! Raquel Welch Then & Now!

Raquel Welch Then & Now! Susan Dey Then & Now!

Susan Dey Then & Now! Tina Louise Then & Now!

Tina Louise Then & Now! Pierce Brosnan Then & Now!

Pierce Brosnan Then & Now!